Content Menu

● Introduction

● The Traditional Practice

● Types of Leaves Used

● The Manufacturing Process

>> 1. Leaf Collection

>> 2. Cleaning and Preparation

>> 3. Softening (if necessary)

>> 4. Shaping

>> 5. Pressing and Drying

>> 6. Finishing

● Industrial Production Methods

● Handmade Production

● Benefits of Leaf Plates

>> Biodegradability

>> Eco-Friendliness

>> Natural Properties

>> Cultural Significance

>> Economic Opportunities

● Challenges and Considerations

>> Durability

>> Availability

>> Scalability

>> Transportation

● Innovations and Future Prospects

● DIY Leaf Plates

● Global Impact and Adoption

● Conclusion

● FAQ

>> 1. Are leaf plates safe to use with all types of food?

>> 2. How long do leaf plates last before decomposing?

>> 3. Can leaf plates be reused?

>> 4. Are there any certifications for leaf plates?

>> 5. How do leaf plates compare in cost to traditional disposable plates?

● Citations:

Introduction

In recent years, there has been a growing concern about the environmental impact of single-use plastics and other non-biodegradable materials. As a result, many people are turning to more eco-friendly alternatives for everyday items, including disposable plates. One innovative solution that has gained popularity is making disposable plates from leaves. This article will explore the process of creating these environmentally friendly plates, their benefits, and the various methods used to produce them.

The Traditional Practice

The use of leaves as plates is not a new concept. In many parts of the world, particularly in South and Southeast Asia, using leaves as disposable plates has been a long-standing tradition. Countries like India, Sri Lanka, and Nepal have been using leaves from various trees, such as banana, sal, and palash, to create biodegradable plates for centuries.

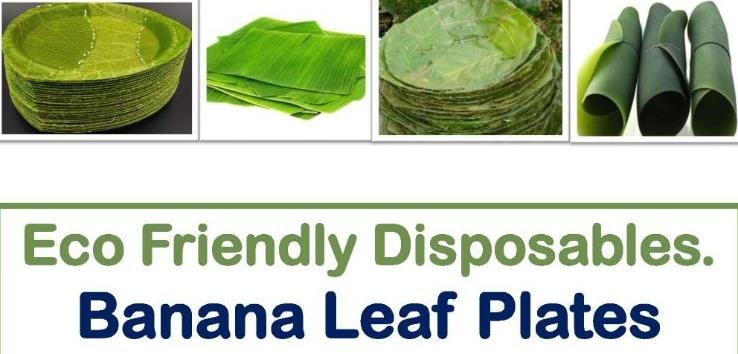

Types of Leaves Used

Several types of leaves can be used to make disposable plates. Some of the most common include:

1. Banana leaves

2. Palash (Flame of the Forest) leaves

3. Sal leaves

4. Areca palm leaves

5. Teak leaves

Each type of leaf has its unique properties, making it suitable for different purposes and food types.

The Manufacturing Process

The process of making disposable plates from leaves can vary depending on the type of leaf used and the desired end product. However, the general steps involved are as follows:

1. Leaf Collection

The first step is to collect suitable leaves. This is typically done by harvesting fallen leaves or carefully removing them from trees without causing damage.

2. Cleaning and Preparation

Once collected, the leaves are thoroughly cleaned to remove any dirt, insects, or debris. This step is crucial to ensure the final product is hygienic and safe for food contact.

3. Softening (if necessary)

Some leaves, like those from the Anthocephalus cadamba tree, may require softening. This is often done using glycerine, which helps make the leaves more pliable and easier to work with[1].

4. Shaping

The leaves are then shaped into the desired form, usually circular or rectangular plates. This can be done manually or using specialized machinery.

5. Pressing and Drying

The shaped leaves are pressed to flatten them and remove excess moisture. This step may involve the use of heat presses or compression molding machines[1].

6. Finishing

Finally, the plates may be trimmed or have additional features added, such as raised edges or compartments.

Industrial Production Methods

For large-scale production, more sophisticated methods are employed.

As seen in the video, the process involves several steps:

1. Cleaning the areca leaf sheaths

2. Drying the cleaned sheaths

3. Pressing the dried sheaths against metal plates using hydraulic machines

4. Trimming and finishing the pressed plates

Handmade Production

For smaller-scale or artisanal production, plates can be made by hand. This method is often used for creating plates from banana leaves or other large, flexible leaves.

The handmade process typically involves:

1. Selecting and cleaning a suitable leaf

2. Folding the leaf to create a bowl or plate shape

3. Securing the folds with small pins or staples (if necessary)

4. Trimming excess material to create a neat edge

Benefits of Leaf Plates

Using disposable plates made from leaves offers several advantages:

Biodegradability

Unlike plastic or styrofoam plates, leaf plates are completely biodegradable. They can be composted or will naturally decompose, returning nutrients to the soil[3].

Eco-Friendliness

The production of leaf plates has a much lower environmental impact compared to traditional disposable plates. They require less energy to produce and don't contribute to plastic pollution[3].

Natural Properties

Many leaves used for plates have natural antibacterial and antiseptic properties, making them a healthier option for food service[3].

Cultural Significance

In many cultures, using leaf plates is a traditional practice with deep cultural roots. Continuing this practice helps preserve cultural heritage while also being environmentally conscious.

Economic Opportunities

The production of leaf plates can provide economic opportunities for rural communities, especially in areas where suitable leaves are abundant[5].

Challenges and Considerations

While leaf plates offer many benefits, there are some challenges to consider:

Durability

Leaf plates may not be as durable as plastic or paper plates, especially when used with very hot or liquid foods.

Availability

The production of leaf plates is often limited to areas where suitable leaves are readily available.

Scalability

Large-scale production can be challenging, as it requires a consistent supply of quality leaves and specialized equipment.

Transportation

Transporting leaf plates over long distances can be less efficient than plastic or paper alternatives due to their bulk and potential for damage.

Innovations and Future Prospects

As interest in sustainable alternatives grows, innovations in leaf plate production continue to emerge. Some companies are exploring ways to enhance the durability and versatility of leaf plates while maintaining their eco-friendly properties.

For example, some manufacturers are developing methods to create more rigid and water-resistant leaf plates by applying natural coatings or using heat-pressing techniques. Others are experimenting with combining different types of leaves or plant fibers to create stronger, more versatile products.

DIY Leaf Plates

For those interested in making their own leaf plates at home, here's a simple method using banana leaves:

1. Select a large, clean banana leaf

2. Cut a circular or square shape from the leaf

3. Fold the edges inward to create a raised rim

4. Secure the folds with small pins or staples

5. Trim any excess material for a neat finish

Global Impact and Adoption

The use of leaf plates is gaining traction worldwide as more people become aware of the need for sustainable alternatives to plastic. In India, where the tradition of using leaf plates (known as "patravali" or "vistaraku") has existed for centuries, there's a resurgence of interest in these eco-friendly options[5].

Many restaurants, especially those serving traditional cuisine, are adopting leaf plates to enhance the dining experience and reduce their environmental footprint. Some countries are even considering regulations to promote the use of biodegradable alternatives like leaf plates in an effort to reduce plastic waste.

Conclusion

Disposable plates made from leaves offer a sustainable and culturally rich alternative to conventional single-use plates. While there are challenges to overcome in terms of large-scale production and distribution, the benefits of these eco-friendly plates are clear. As we continue to seek ways to reduce our environmental impact, leaf plates represent a promising solution that combines tradition with modern sustainability needs.

By supporting the production and use of leaf plates, we can contribute to reducing plastic waste, preserving cultural practices, and promoting more sustainable consumption habits. Whether used in traditional settings, eco-conscious restaurants, or everyday households, leaf plates demonstrate that sometimes, the most innovative solutions can be found in nature itself.

FAQ

1. Are leaf plates safe to use with all types of food?

Most leaf plates are safe for a wide variety of foods. However, very hot or highly acidic foods may not be suitable for some types of leaf plates. It's best to check the specific properties of the leaf plate you're using.

2. How long do leaf plates last before decomposing?

The decomposition time can vary depending on the type of leaf and environmental conditions. Generally, leaf plates will begin to decompose within a few weeks to a few months when composted or disposed of in a natural environment.

3. Can leaf plates be reused?

While leaf plates are designed for single use, some sturdier varieties can be gently washed and reused a few times. However, it's important to inspect them for any signs of degradation before reuse.

4. Are there any certifications for leaf plates?

Some manufacturers obtain certifications for their leaf plates, such as compostability certifications from organizations like the Biodegradable Products Institute. These certifications can provide assurance of the product's eco-friendly properties.

5. How do leaf plates compare in cost to traditional disposable plates?

The cost of leaf plates can vary depending on the production method and location. In areas where suitable leaves are abundant, they can be very cost-effective. However, in other regions, they may be more expensive than mass-produced plastic or paper plates due to transportation and production costs.

Citations:

[1] https://ijcrt.org/papers/IJCRT2111032.pdf

[2] https://www.youtube.com/watch?v=cMXIZ1hFZ8M

[3] https://www.youtube.com/watch?v=P1td1JYRzNY

[4] https://www.alamy.com/stock-photo/leaf-plates.html

[5] https://www.reddit.com/r/Damnthatsinteresting/comments/ovorf9/these_plates_are_made_from_leaves/

[6] https://www.youtube.com/watch?v=61IBKTD03fM

[7] https://www.youtube.com/watch?v=Nj8YCbZz4k8

[8] https://www.youtube.com/watch?v=I_r5Wm5cuJU

[9] https://greenpaperproducts.com/collections/compostable-plates/palm-leaf

[10] https://www.reddit.com/r/videos/comments/qxg4hb/making_disposable_plates_from_plant_leaves/