Content Menu

● Introduction to Disposable Plate Making Machines

>> Benefits of Disposable Plate Making Machines

● Disposable Plate Making Machine Price

● Applications of Disposable Plate Making Machines

>> Food Services

>> Event Planning

>> Packaging Industry

● Cost-Effective Strategies for Paper Plate Manufacturing

● Market Trends in Disposable Tableware

● Technological Innovations in Disposable Plate Making

>> Integration of Technology

● Challenges and Solutions in Plate Making

>> Common Issues and Solutions

● Conclusion

● FAQs

>> 1. What is the typical production capacity of a fully automatic disposable plate making machine?

>> 2. How do disposable plate making machines contribute to environmental sustainability?

>> 3. What factors influence the disposable plate making machine price?

>> 4. What are the primary applications of disposable plate making machines?

>> 5. How do disposable plate making machines enhance cost efficiency?

● Citations:

Disposable plate making machines have become increasingly popular due to their role in producing eco-friendly disposable tableware. These machines are crucial for businesses seeking to capitalize on the growing demand for sustainable products. However, the question remains: are disposable plate making machines affordable? This article will delve into the pricing, benefits, and applications of these machines, providing insights into their affordability and value proposition.

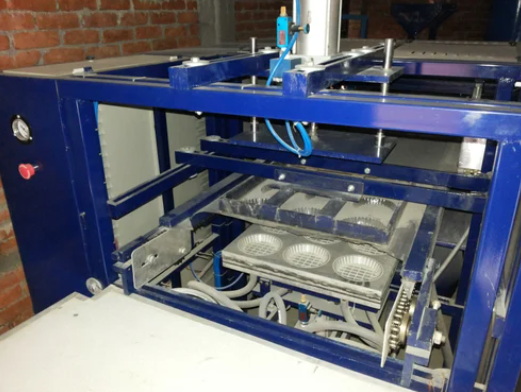

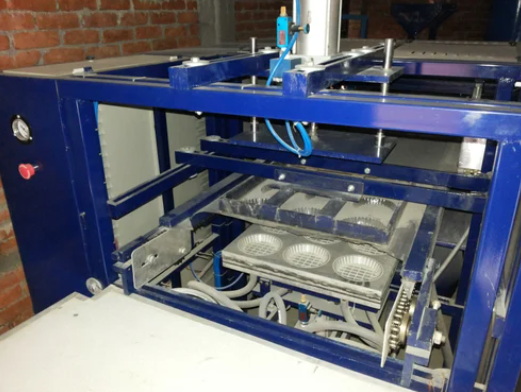

Introduction to Disposable Plate Making Machines

Disposable plate making machines are designed to manufacture paper plates from raw materials like paper and coatings. These machines automate the process of feeding, forming, pressing, cutting, and outputting paper plates efficiently. They are widely used in the food service industry, event planning, and packaging sectors due to their ability to produce high volumes of hygienic and durable paper plates.

Benefits of Disposable Plate Making Machines

1. Environmental Benefits: These machines use biodegradable materials, reducing environmental impact by replacing plastic and foam products.

2. Cost Efficiency: Fully automatic machines minimize labor costs and material waste, increasing production efficiency.

3. Customization: They allow for customized production to meet specific market demands for unique designs and sizes.

4. Health and Safety: Disposable paper plates eliminate cross-contamination risks, adhering to food-grade hygiene standards.

Disposable Plate Making Machine Price

The price of disposable plate making machines varies significantly based on their type and capacity. Here are some examples:

- Fully Automatic Machines: Prices range from $8,000 to $28,000. These machines are ideal for large-scale operations, producing up to 3,000 plates per hour.

Fully automatic machines offer high production capacity and are suitable for businesses with large demand. They are typically made of mild steel and operate on single-phase power, requiring about 1 HP for operation[1].

- Semi-Automatic Machines: Priced between $5,000 and $8,000, these machines offer a balance between cost and productivity, suitable for medium-sized businesses.

Semi-automatic machines are more affordable and require some manual intervention, making them ideal for smaller operations or startups looking to scale up gradually.

- Manual Machines: The most affordable option, priced from $2,000 to $5,000. They are suitable for small businesses or startups with low-volume production needs.

Manual machines are cost-effective for small-scale production and can be a good starting point for new businesses.

Applications of Disposable Plate Making Machines

Food Services

Disposable plate making machines are essential in the food service industry, including fast-food chains, coffee shops, and takeout services. They provide high volumes of hygienic paper plates, which are crucial for maintaining food safety standards.

In the food service sector, these machines help reduce labor costs associated with washing dishes and minimize the risk of cross-contamination. This aligns with the growing trend towards eco-friendly and sustainable practices in the industry.

Event Planning

These machines are also used in event planning for weddings, parties, and exhibitions. They offer customized paper plates that can be branded with logos or designs, enhancing brand visibility.

Customized paper plates are a marketing tool for events, allowing businesses to promote their brand while contributing to sustainability efforts.

Packaging Industry

In the packaging sector, disposable plate making machines produce strong, customizable paper plates for food packaging and retail supply. This helps clients promote their brand with printed logos and designs.

The packaging industry benefits from these machines by offering sustainable packaging solutions that appeal to environmentally conscious consumers.

Cost-Effective Strategies for Paper Plate Manufacturing

To make paper plate manufacturing more cost-effective, several strategies can be employed:

- Invest in Used Equipment: Purchasing second-hand equipment can cut initial costs by up to 40% compared to new models[3].

- Start Small: Begin with a limited production capacity to validate your business model before scaling up, minimizing initial paper plate production costs[3].

- Utilize Local Suppliers: Sourcing raw materials locally can reduce shipping costs and help build relationships with suppliers[3].

- Share Facilities: Partnering with existing manufacturers to share space can lower facility lease or purchase costs[3].

Market Trends in Disposable Tableware

The disposable tableware market is experiencing significant growth, driven by consumer demand for eco-friendly products. The market is expected to reach USD 36.92 billion by 2025 and grow at a CAGR of 4.45% to reach USD 45.90 billion by 2030[7]. Key trends include:

- Eco-Friendly Materials: There is a growing preference for biodegradable materials such as bamboo, sugarcane bagasse, and cornstarch[2][4].

- Customization and Innovation: Manufacturers are offering innovative and customizable designs to cater to consumer preferences for aesthetically pleasing products[4].

Technological Innovations in Disposable Plate Making

Technological advancements in disposable plate making machines have improved efficiency and customization capabilities. These machines can now produce a wide range of plate sizes and designs, meeting specific market demands.

Integration of Technology

- Automated Production: Fully automatic machines ensure consistent quality and high production rates, reducing manual errors and labor costs.

- Customizable Designs: Machines can be equipped with advanced printing systems to produce customized designs, enhancing brand visibility and marketing opportunities.

Challenges and Solutions in Plate Making

Common challenges in plate making include issues with plate quality and production efficiency. Solutions involve optimizing machine settings, using high-quality raw materials, and maintaining equipment regularly.

Common Issues and Solutions

1. Shallow Images: Causes include overexposure and insufficient plate density. Solutions involve adjusting exposure times and using plates with fine textures[5].

2. Disappearing Images: Causes include long exposure times and inconsistent plate coating. Solutions involve determining correct exposure times and ensuring stable lighting conditions[5].

Conclusion

Disposable plate making machines are indeed affordable, especially when considering their long-term benefits and cost savings. They offer a sustainable solution for businesses looking to capitalize on the growing demand for eco-friendly products. By investing in these machines, companies can enhance their production efficiency, reduce environmental impact, and increase brand visibility through customization options.

FAQs

1. What is the typical production capacity of a fully automatic disposable plate making machine?

Fully automatic machines can produce up to 3,000 plates per hour, making them ideal for large-scale operations.

2. How do disposable plate making machines contribute to environmental sustainability?

These machines use biodegradable materials like paper, reducing the environmental impact by replacing plastic and foam products.

3. What factors influence the disposable plate making machine price?

The price is influenced by the machine's type (fully automatic, semi-automatic, or manual), production capacity, and features such as customization options and automation level.

4. What are the primary applications of disposable plate making machines?

They are widely used in food services, event planning, and the packaging industry for producing hygienic and customizable paper plates.

5. How do disposable plate making machines enhance cost efficiency?

They minimize labor costs by requiring fewer operators and reduce material waste through efficient production processes.

Citations:

[1] https://www.guptatrader.com/paper-plate-making-machine.html

[2] https://ecofreek.com/biodegradable/6-best-biodegradable-plates-for-your-sustainable-business/

[3] https://businessplan-templates.com/blogs/startup-costs/paper-plate-manufacturing

[4] https://www.gminsights.com/industry-analysis/disposable-tableware-market

[5] https://www.zxprinter.com/support/common-issues-in-plate-making-and-solutions.html

[6] https://www.sahilgraphics.com/blogs/what-are-the-benefits-of-paper-plate-machines/

[7] https://www.mordorintelligence.com/industry-reports/global-disposable-tableware-market

[8] https://www.billerud.com/products/packaging-materials/formable-paper/paper-plates

[9] https://www.assemblies.com/cost-saving-strategies-food-and-supplement-packaging/

[10] https://www.linkedin.com/pulse/hydraulic-paper-plate-making-machine-market-1hh9f/

[11] https://greentableware.hk/en-us/home/about

[12] https://finmodelslab.com/blogs/startup-costs/paper-plate-manufacturing-startup-costs

[13] https://www.verifiedmarketresearch.com/product/disposable-tableware-market/

[14] https://www.solutigreen.com/info-detail/opportunities-and-challenges-for-becoming-a-paper-cup-paper-plate-manufacturer

[15] https://www.justdial.com/Sira/Paper-Plate-Making-Machine-Dealers/nct-10836418

[16] https://greenpaperproducts.com/collections/compostable-plates

[17] https://pritienterprise.com/how-to-start-paper-plate-business-investment-profit-margin-and-marketing/

[18] https://www.globenewswire.com/news-release/2024/08/07/2926025/28124/en/Tableware-Market-Trends-Report-2024-2030-Blending-Versatile-and-Beautiful-Styles-with-Functionality-Durability-and-Performance.html

[19] https://repurpose.global/blog/post/the-problem-with-plastic-plates-and-a-possible-solution

[20] https://www.konita-hk.com/info/problems-encountered-in-plate-making-and-print-28050458.html