Content Menu

● Introduction to Disposable Glass Plate Machines

>> Benefits of Disposable Glass Plate Machines

● Market Overview

>> Disposable Glass Plate Making Machine Price

>>> Example Prices:

● Second-Hand Machines: Pros and Cons

>> Pros of Second-Hand Machines

>> Cons of Second-Hand Machines

● How to Evaluate a Second-Hand Machine

● Market Trends and Future Outlook

>> Impact of Sustainability Initiatives

>> Technological Advancements

● Case Studies: Successful Implementations

>> Example of a Successful Business Model

● Challenges and Opportunities

● Strategies for Success

● Conclusion

● Frequently Asked Questions

>> 1. What are the primary benefits of using a disposable glass plate making machine?

>> 2. How does the price of a new disposable glass plate machine compare to a second-hand one?

>> 3. What factors should I consider when evaluating a second-hand machine?

>> 4. Are second-hand machines reliable for continuous production?

>> 5. Can I customize the plates produced by a disposable glass plate machine?

The decision to purchase a second-hand disposable glass plate machine can be a complex one, influenced by various factors such as cost, efficiency, and environmental considerations. In this article, we will delve into the pros and cons of buying used machinery, explore the market for disposable glass plate machines, and discuss the disposable glass plate making machine price.

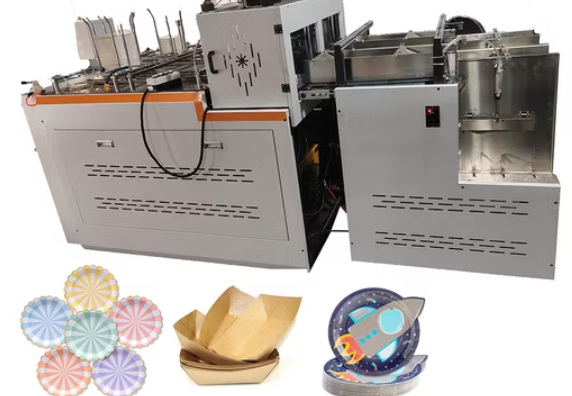

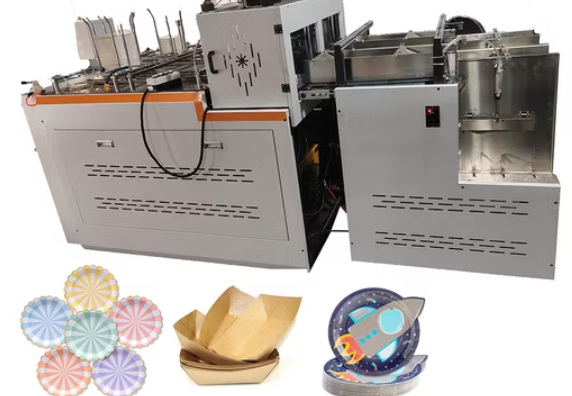

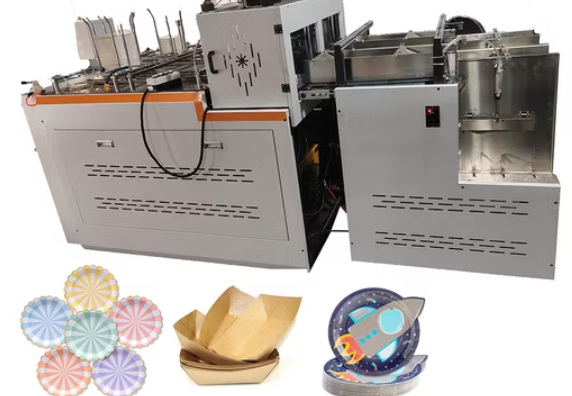

Introduction to Disposable Glass Plate Machines

Disposable glass plate machines are designed to produce eco-friendly alternatives to traditional plastic or foam plates. These machines use paper or biodegradable materials to create disposable plates, which are increasingly popular due to their environmental benefits. The process involves feeding raw materials into the machine, which then shapes and cuts them into plates of various sizes.

Benefits of Disposable Glass Plate Machines

1. Environmental Benefits: These machines produce plates from biodegradable materials, reducing plastic waste and supporting sustainability initiatives.

2. Cost-Effective: The initial investment in a second-hand machine can be lower compared to purchasing new equipment.

3. Customization: Plates can be customized with logos or designs, making them suitable for branding and marketing purposes.

Market Overview

The market for disposable glass plate machines is growing, driven by the demand for eco-friendly packaging solutions. Manufacturers offer a range of machines with varying production capacities and automation levels.

Disposable Glass Plate Making Machine Price

The price of a disposable glass plate making machine can vary significantly based on factors such as production capacity, automation level, and condition (new or used). For instance, a basic automatic machine might start at around ₹6,40,000 (approximately $8,000 USD), while more advanced models with higher production capacities can cost upwards of ₹7,50,000 (about $9,500 USD).

Example Prices:

- Basic Automatic Machine: ₹6,40,000 (around $8,000 USD)

- Advanced Automatic Machine: ₹7,50,000 (about $9,500 USD)

- High-Capacity Machine: ₹60,00,000 (approximately $75,000 USD)

Second-Hand Machines: Pros and Cons

Pros of Second-Hand Machines

1. Cost Savings: Purchasing a used machine can significantly reduce initial investment costs.

2. Quick Availability: Second-hand machines are often readily available for immediate use.

3. Environmental Benefits: Reusing existing machinery reduces waste and supports sustainability.

Cons of Second-Hand Machines

1. Maintenance Costs: Older machines may require more frequent repairs and maintenance.

2. Limited Warranty: Used machines typically do not come with a manufacturer's warranty.

3. Potential for Obsolescence: Older models might not be as efficient or feature-rich as newer models.

How to Evaluate a Second-Hand Machine

When considering a second-hand disposable glass plate machine, it's crucial to evaluate its condition, performance, and maintenance history. Here are some steps to follow:

1. Inspect the Machine: Look for signs of wear and tear, and ensure all components are in working order.

2. Check Maintenance Records: Obtain records of past maintenance and repairs to assess potential future costs.

3. Test the Machine: Run the machine to ensure it operates smoothly and efficiently.

Market Trends and Future Outlook

The demand for eco-friendly products is on the rise globally, driven by consumer awareness and regulatory pressures. This trend is expected to continue, making disposable glass plate machines a promising investment for businesses in the packaging and hospitality sectors.

Impact of Sustainability Initiatives

Governments and organizations worldwide are implementing sustainability initiatives aimed at reducing plastic waste. This shift towards eco-friendly alternatives has created a favorable market environment for disposable glass plate machines.

Technological Advancements

Advancements in technology have led to more efficient and cost-effective machines. Even second-hand models can benefit from recent improvements in automation and material handling, making them more viable options for businesses.

Case Studies: Successful Implementations

Several companies have successfully integrated disposable glass plate machines into their operations, achieving significant environmental benefits and cost savings. For example, a restaurant chain in Europe reported a 30% reduction in waste disposal costs after switching to biodegradable plates produced by these machines.

Example of a Successful Business Model

A small startup in Asia began producing biodegradable plates using a second-hand machine. By focusing on customization and partnering with local events, they were able to increase their market share and achieve profitability within the first year.

Challenges and Opportunities

While the market for disposable glass plate machines presents numerous opportunities, there are also challenges to consider:

1. Raw Material Costs: Fluctuations in raw material prices can affect production costs.

2. Competition: The market is becoming increasingly competitive as more manufacturers enter the scene.

3. Regulatory Compliance: Ensuring compliance with environmental regulations can be complex and costly.

Strategies for Success

To succeed in this market, businesses should focus on:

1. Innovation: Continuously update machinery and processes to improve efficiency and reduce costs.

2. Marketing: Highlight the environmental benefits and customization options to attract customers.

3. Partnerships: Collaborate with suppliers and distributors to secure stable raw material supplies and expand market reach.

Conclusion

Purchasing a second-hand disposable glass plate machine can be a viable option for businesses looking to reduce costs while contributing to environmental sustainability. However, it's essential to weigh the pros and cons carefully and conduct thorough evaluations before making a purchase.

Frequently Asked Questions

1. What are the primary benefits of using a disposable glass plate making machine?

The primary benefits include environmental sustainability, cost-effectiveness, and customization options for branding purposes.

2. How does the price of a new disposable glass plate machine compare to a second-hand one?

New machines generally cost more than used ones, with prices starting from around ₹6,40,000 for basic models. Second-hand machines can offer significant cost savings.

3. What factors should I consider when evaluating a second-hand machine?

Key factors include the machine's condition, maintenance history, and performance. It's also important to inspect the machine thoroughly and check for any needed repairs.

4. Are second-hand machines reliable for continuous production?

While second-hand machines can be reliable, they may require more maintenance than new machines. Regular checks and maintenance are crucial to ensure continuous operation.

5. Can I customize the plates produced by a disposable glass plate machine?

Yes, many machines allow for customization with logos or designs, making them suitable for branding and marketing purposes.