Content Menu

● Introduction to Biodegradable Plates

>> Raw Materials Used

● How Biodegradable Disposable Plate Making Machines Work

>> 1. Pulping Process

>> 2. Refining

>> 3. Forming

>> 4. Drying

>> 5. Finishing

● Types of Biodegradable Plate Making Machines

● Environmental Benefits

● Market Demand and Future Prospects

>> Key Drivers of Market Growth

● Production Process Innovations

>> Technological Advancements

● Impact on the Environment

>> Decomposition Timeline

● Conclusion

● FAQs

>> 1. What Materials Are Used in Biodegradable Plates?

>> 2. How Long Do Biodegradable Plates Take to Decompose?

>> 3. Can Biodegradable Plates Be Used in Microwaves?

>> 4. Are Biodegradable Plates More Expensive Than Plastic Plates?

>> 5. Can Biodegradable Plates Be Recycled?

● Citations:

In recent years, the demand for eco-friendly products has surged, driven by growing concerns about environmental pollution and the need to reduce plastic waste. One of the innovative solutions in this space is the biodegradable disposable plate making machine, which produces plates from natural materials like sugarcane bagasse, wheat straw, and bamboo. These machines are crucial for manufacturing sustainable tableware that can easily decompose, reducing the environmental impact of traditional plastic plates.

Introduction to Biodegradable Plates

Biodegradable plates are made from renewable resources that can naturally break down into organic matter. Unlike plastic, which takes hundreds of years to decompose, biodegradable plates typically decompose within a few months under proper conditions. This shift towards sustainable tableware is not only beneficial for the environment but also aligns with consumer preferences for eco-friendly products.

Raw Materials Used

The most common raw materials used in biodegradable plate production include:

- Sugarcane Bagasse: A fibrous byproduct of sugarcane processing, known for its durability and heat resistance.

- Wheat Straw: A byproduct of wheat farming, used for lightweight plates and containers.

- Bamboo Fiber: Naturally strong and flexible, often used for plates and utensils.

- Palm Leaves: Dried areca palm leaves pressed into shapes for plates and bowls.

- Cornstarch Polylactic Acid (PLA): Derived from cornstarch, PLA is a bio-based and compostable material, offering the same functionality as traditional plastic but without the environmental drawbacks[8].

How Biodegradable Disposable Plate Making Machines Work

The process of making biodegradable plates involves several stages, from raw material preparation to final product packaging. Here's an overview of how these machines operate:

1. Pulping Process

The raw materials are processed into a pulp using a pulper. This involves breaking down the fibers into a consistent mixture that can be molded into various shapes. For example, sugarcane bagasse is first collected and processed to remove impurities and extract the pulp[7].

2. Refining

The pulp is refined to achieve the desired consistency and fiber length. This step ensures that the final product is strong and durable. Refining can involve mechanical or chemical treatments to enhance the pulp's properties.

3. Forming

The refined pulp is then poured into molds where it takes the shape of plates, bowls, or other tableware items. The molds are designed to produce specific shapes and sizes. The forming process can be done using various types of machines, including semi-automatic, fully automatic, and robotic machines[1].

4. Drying

After forming, the products are dried to remove excess moisture. This can be done using heat or natural sunlight. Proper drying is crucial to ensure the plates are sturdy and resistant to moisture.

5. Finishing

The dried products are then trimmed to remove excess edges and polished to improve their appearance. Some machines may apply a waterproof coating to enhance durability. This step is important for ensuring the plates are suitable for use with food.

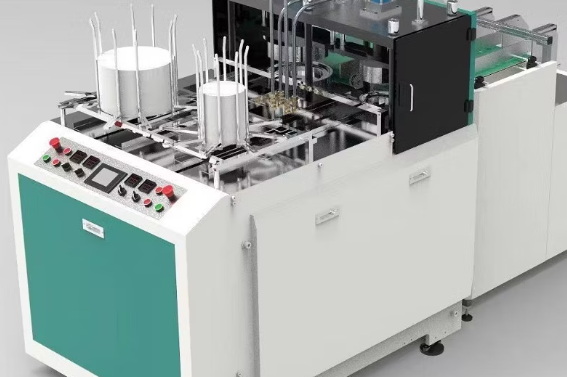

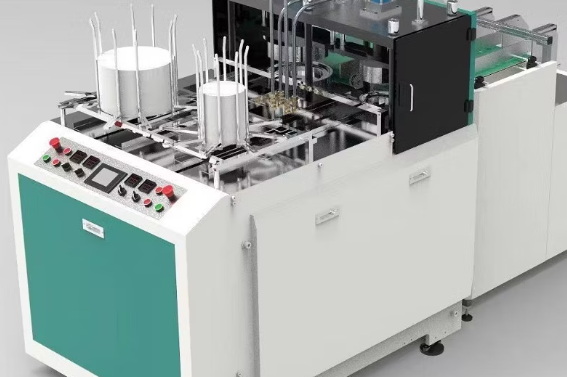

Types of Biodegradable Plate Making Machines

Biodegradable plate making machines come in various types, each suited for different production needs and scales:

- Semi-Automatic Machines: These require manual intervention at several stages of production. They are cost-effective and suitable for small-scale operations.

- Fully Automatic Machines: Equipped with advanced automation, these machines can produce plates continuously without manual intervention. They are ideal for large-scale production and offer high efficiency and consistency in output[1].

- Robotic Machines: These machines use robotic arms for precise handling and molding, ensuring high-quality products with minimal human error. Robotic machines are particularly useful for complex designs and shapes.

- Hydraulic Presses: Used for applying high pressure to mold the pulp into the desired shape. Hydraulic presses are essential for ensuring the plates are dense and durable.

Environmental Benefits

The use of biodegradable disposable plate making machines offers several environmental benefits:

- Reduces Plastic Waste: By replacing plastic plates with biodegradable ones, we significantly reduce the amount of plastic waste that ends up in landfills and oceans.

- Lower Carbon Footprint: The production process for biodegradable plates relies on renewable resources and consumes less energy compared to plastic manufacturing.

- Non-Toxic Decomposition: Biodegradable plates decompose into organic matter without releasing toxic chemicals into the environment.

Market Demand and Future Prospects

The demand for biodegradable tableware is increasing globally, driven by consumer preference for eco-friendly products and regulatory pressures to reduce plastic use. This trend presents a lucrative business opportunity for entrepreneurs and manufacturers looking to invest in sustainable technologies. The global biodegradable tableware market is projected to grow significantly, with a current value of USD 16.21 billion expected to reach USD 24.72 billion by 2030[4].

Key Drivers of Market Growth

- Environmental Implications: Disposable plastic or foam tableware takes centuries to decompose, causing long-term pollution. Biodegradable alternatives decompose much faster, reducing plastic pollution and pressure on landfills[4].

- Resource Conservation: Producing disposable plastic food plates consumes non-renewable petroleum resources. Renewable resources like pulpboard help conserve these resources and promote sustainability[4].

- Government Policies and Regulations: Many governments have issued plastic restriction orders, making biodegradable products a preferred alternative due to their biodegradable characteristics[4].

Production Process Innovations

Innovations in the production process are crucial for improving efficiency and reducing costs. For instance, the use of advanced machinery like fully automatic forming machines can significantly increase production capacity while maintaining product quality. Companies like Parason Machinery in India are leading the way in developing state-of-the-art biodegradable plate making machines[1].

Technological Advancements

Technological advancements in biodegradable plate production include the development of new materials and manufacturing processes. For example, the use of wood-based or plant-based refuse materials converted into a resin for producing disposable dishes and utensils is becoming more prevalent[2]. These innovations not only enhance product quality but also contribute to a more sustainable production process.

Impact on the Environment

Using biodegradable plates has a positive impact on the environment by reducing waste and pollution. These plates can easily decompose into natural materials, reducing landfill waste and minimizing environmental harm[5]. Additionally, the composting process of biodegradable plates produces nutrient-rich soil, which can be used in agriculture, further supporting sustainable practices[5].

Decomposition Timeline

Biodegradable plates typically take between 3 to 6 months to decompose fully if properly composted. However, in landfills, they may take longer due to the lack of oxygen and microbes necessary for decomposition[5]. Proper disposal methods are crucial for maximizing the environmental benefits of biodegradable plates.

Conclusion

In conclusion, biodegradable disposable plate making machines play a crucial role in the production of sustainable tableware. By utilizing natural materials and minimizing environmental impact, these machines contribute to a greener future. As technology advances and consumer awareness grows, the demand for biodegradable products will continue to rise, making this industry a promising sector for investment and innovation.

FAQs

1. What Materials Are Used in Biodegradable Plates?

Biodegradable plates are made from natural materials such as sugarcane bagasse, wheat straw, bamboo fibers, palm leaves, and biodegradable cornstarch (PLA). These materials are renewable and can easily decompose into organic matter.

2. How Long Do Biodegradable Plates Take to Decompose?

The decomposition time for biodegradable plates varies depending on the material and environmental conditions. Generally, they decompose within 3 to 6 months in composting facilities, but may take longer in landfills.

3. Can Biodegradable Plates Be Used in Microwaves?

Most biodegradable plates are not suitable for microwave use due to the risk of deformation or burning. However, some materials like sugarcane bagasse plates might be microwave-safe, but it's always best to check the manufacturer's guidelines.

4. Are Biodegradable Plates More Expensive Than Plastic Plates?

Yes, biodegradable plates are typically more expensive than traditional plastic plates due to the higher cost of raw materials and eco-friendly production processes. However, they offer long-term environmental benefits and align with consumer preferences for sustainable products.

5. Can Biodegradable Plates Be Recycled?

Biodegradable plates are generally not recyclable in the traditional sense but should be composted instead. Composting allows them to break down into nutrient-rich organic matter that can be reused in agriculture.

Citations:

[1] https://worldpapermill.com/biodegradable-plate-making-machine/

[2] https://patents.google.com/patent/US20130081972A1/en

[3] https://plamfg.com/biodegradable-plates-and-cups-manufacturer/

[4] https://www.bestongroup.com/biodegradable-plate-making-machine/

[5] https://naturalpanaa.com.au/the-impact-of-using-biodegradable-plates-on-our-environment/

[6] https://sciendo.com/pdf/10.2478/rtuect-2020-0054

[7] https://www.frontiersin.org/journals/sustainable-food-systems/articles/10.3389/fsufs.2023.1220324/pdf

[8] https://kasem-international.com/5-innovative-materials-revolutionizing-sustainable-tableware/

[9] https://www.accessnewswire.com/newsroom/en/industrial-and-manufacturing/disposable-plates-market-to-expand-at-36-cagr-through-2035-driven-by-fo-983798

[10] https://cosmosecofriends.com/the-rise-of-biodegradable-plates-a-sustainable-dining-solution/

[11] https://www.hspulpmolding.com/the-future-of-biodegradable-tableware-advances-in-innovative-biodegradable-machines/

[12] https://enterclimate.com/blog/start-a-biodegradable-plate-manufacturing-business/

[13] https://ecofreek.com/biodegradable/6-best-biodegradable-plates-for-your-sustainable-business/

[14] https://www.linkedin.com/pulse/paper-plate-making-machine-market-growth-future-koace/

[15] https://sustainability.tufts.edu/wp-content/uploads/LifeCycleAnalysisPlasticPlatevsCeramic.pdf

[16] https://www.fareastpulpmolding.com/biodegradable-disposable-plate-making-machine/

[17] https://naturalpanaa.com.au/biodegradable-plates-production/

[18] https://greenpaperproducts.com/collections/compostable-plates

[19] https://www.linkedin.com/pulse/biodegradable-plate-making-machine-food-packaging-beston-group--vxmac

[20] https://www.linkedin.com/pulse/environmental-impact-traditional-vs-compostable-plates-what-sh19c