Content Menu

● Industry Trends and the Drive for Innovation

● Hebei Gurui's R&D Philosophy and Organizational Structure

● Material Science: The Core of Competitive Advantage

>> Advanced Materials for Performance and Safety

>> High-Temperature Resistance and Leakproofing

>> Specialized Material Blends

● Intelligent Manufacturing: Beyond Traditional Processes

>> Automated Production Lines

>> Process Optimization

>> Real-Time Monitoring and Data Utilization

● Product Design Centered Around the User

>> Functional Usability

>> Prototyping for Rapid Innovation

● Commitment to Eco-Friendly Innovation

>> Biodegradable and Compostable Materials

>> Waste Reduction in Production

>> Energy and Carbon Optimization

● Innovation Through Partnerships

● Consistency Through Quality Control

>> In-line Inspection Tools

>> Continuous Feedback Loops

● Conclusion

● Frequently Asked Questions (FAQs)

>> 1. What is the main focus of Hebei Gurui's R&D team?

>> 2. How does Hebei Gurui ensure its packaging is environmentally friendly?

>> 3. What steps are taken to ensure product quality?

>> 4. Are customization options available for different clients?

>> 5. How does Gurui stay ahead of packaging trends?

In the fiercely competitive market of food packaging, innovation is not just an advantage—it's a necessity. From fast-food restaurants and meal delivery services to eco-conscious consumers, demand is skyrocketing for reliable, sustainable, and safe food containers. At the heart of this movement, Hebei Gurui stands as a leading manufacturer that prioritizes research and development in the creation of bowls and lids. Unlike brands that merely react to market trends, Hebei Gurui continuously shapes and leads industry standards.

Much of this success lies in the expertise, agility, and forward-thinking approach of the company's R&D team. This article explores how that team is enhancing the competitiveness of Hebei Gurui's bowls and lids, solidifying the company's reputation as a trusted name in the global packaging domain.

Industry Trends and the Drive for Innovation

The packaging sector is in the midst of a transformative shift. Disposable and reusable containers are no longer judged solely on cost or availability. Customers now expect packaging that is functional, aesthetically pleasing, easy to handle, and—most importantly—sustainable.

Rising consumer awareness around plastic pollution and new governmental regulations on food packaging are pushing manufacturers to shift their priorities toward environmental performance. The need for intelligent, adaptable designs that support automation and logistic efficiency is also more pressing than ever. In such a dynamic environment, the role of research and development has evolved from an auxiliary function to a business-defining operation.

Hebei Gurui's R&D Philosophy and Organizational Structure

At Hebei Gurui, the R&D team is more than just a department—it is the engine behind virtually every product advancement. Combining specialists in material engineering, product design, process optimization, and market analysis, the team is structured to be agile, responsive, and customer-focused.

The working philosophy hinges on five core pillars:

1. Continuous Innovation – Never rest on past achievements; always ask what's next.

2. Multidisciplinary Collaboration – Canvas ideas across departments and integrate technical expertise with real-world usability.

3. Customer Integration – Treat customer feedback as co-development input, not just post-sale response.

4. Sustainability – Balance environmental responsibility with product performance and cost.

5. Data-Driven Decisions – Gather insights through testing and analysis to guide product evolution.

The result is an R&D division that acts nimbly, aligning development timelines with market expectations while achieving long-term objectives in sustainability and design excellence.

Material Science: The Core of Competitive Advantage

Advanced Materials for Performance and Safety

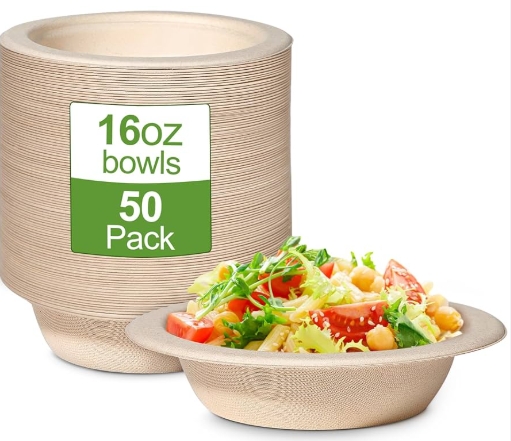

To boost competitiveness, Hebei Gurui's R&D team continuously evaluates and incorporates advanced raw materials that deliver better durability, flexibility, and food safety reassurance. These include food-grade polymers, plant-based composites, and anti-microbial additives to meet different client requirements.

High-Temperature Resistance and Leakproofing

One area where Gurui excels is in the engineering of lids and bowls that withstand temperature fluctuations—whether it's carrying hot soup or storing a cold dessert. The material selection ensures no warping, cracking, or safety hazard under thermal stress.

Specialized Material Blends

Hebei Gurui also leads in formulating proprietary material composites that result in products being both lightweight and strong. These custom formulations often integrate features like enhanced transparency, increased toughness, or even biodegradable properties, depending on market needs.

Intelligent Manufacturing: Beyond Traditional Processes

Automated Production Lines

With the help of the R&D team, Gurui has optimized its production lines to embrace automation in every critical stage—from precision molding to sealing checks. This speeds up the process while ensuring consistency in product quality. Automated sensors, conveyors, and robotic arms reduce labor mistakes and increase throughput.

Process Optimization

Product development doesn't stop at design. The R&D team is deeply involved in refining the manufacturing process itself. This includes:

- Improving mold design to reduce material waste.

- Designing equipment that lowers energy consumption.

- Streamlining production layouts for faster transitions between product batches.

Real-Time Monitoring and Data Utilization

Sophisticated data collection tools on the factory floor continuously track product dimensions, surface integrity, and sealing capabilities. This ensures timely intervention when anomalies are detected—minimizing waste, rework, and customer complaints.

Product Design Centered Around the User

Functional Usability

Every bowl and lid produced by Hebei Gurui is subjected to iterative user-experience testing. The goal is to ensure that each component feels intuitive and secure, whether it's being handled by a restaurant worker during lunch rush or a consumer reheating dinner at home.

The design process assesses multiple factors:

- The ease of snapping lids onto bowls.

- Airtight seal performance to prevent spillage.

- The ability to stack multiple containers efficiently without risk of toppling.

Prototyping for Rapid Innovation

Using 3D modeling and small-scale fabrication, the R&D team can turn ideas into tangible prototypes quickly. Engineers then test these for load-bearing strength, compatibility with microwaves or dishwashers, and long-term performance under repeated use.

This iterative cycle ensures faster time to market while minimizing flaws upon mass production.

Commitment to Eco-Friendly Innovation

Biodegradable and Compostable Materials

Rising to the challenges of today's ecological demands, Hebei Gurui's R&D efforts are heavily aligned with identifying and utilizing sustainable materials. Whether it's bamboo fiber blends, sugarcane bagasse, or starch-based polymers, the aim is to reduce reliance on petroleum-based plastics.

Waste Reduction in Production

Optimized machine calibration and intelligent mold design significantly reduce plastic scrap during manufacturing. In addition, defective parts that do emerge are sent for reprocessing instead of landfill disposal.

Energy and Carbon Optimization

Eco-conscious packaging isn't just about materials—it's about every aspect of the process. Hebei Gurui's manufacturing is being continuously upgraded to reduce carbon emissions, integrating low-energy heating systems and evaluating greener logistics solutions for raw materials and distribution.

Innovation Through Partnerships

Innovation at Gurui is not a solitary pursuit. The R&D team actively partners with a range of external stakeholders to accelerate technology adoption.

- Research Institutions: Joint experiments in bio-based materials and plastic alternatives.

- Technology Providers: Access to early-stage technologies such as anti-leak coatings, smart labeling, and heat-resistant bio-polymers.

- Clients and Retailers: Customized product development based on volume, function, or branding needs.

These collaborations provide mutual benefits while reinforcing Gurui's commitment to product relevance and excellence.

Consistency Through Quality Control

Improving competitiveness isn't only about innovation—it's about ensuring consistency and consumer confidence.

In-line Inspection Tools

The R&D team works with Quality Assurance to integrate smart cameras, laser thickness scanners, and defect detection software directly into production lines.

Continuous Feedback Loops

Inspection data is fed back into R&D to revise designs, tooling adjustments, or material selections in real-time. This cycle results in consistently high standards across all product lines and faster response to customer and market needs.

Conclusion

Hebei Gurui's competitive edge in producing high-quality bowls and lids lies not in a singular invention, but in the deeply rooted philosophy of continuous, science-backed innovation. By integrating advanced materials, intelligent production systems, precise user-centric design, and environmentally responsible practices, their R&D team plays a pivotal role in driving the future of food packaging.

This synergy between skill, science, and sustainability ensures that Hebei Gurui remains not only a manufacturer of containers but a pioneer in how food packaging evolves in the 21st century.

Frequently Asked Questions (FAQs)

1. What is the main focus of Hebei Gurui's R&D team?

The R&D team focuses on developing innovative, user-friendly, and eco-conscious packaging products. They strive to enhance material selection, manufacturing efficiency, and product usability to stay ahead in a competitive market.

2. How does Hebei Gurui ensure its packaging is environmentally friendly?

Gurui's R&D team works with biodegradable materials and designs processes that generate minimal waste. They also use recyclable packing components and aim for energy-efficient production methods.

3. What steps are taken to ensure product quality?

The company integrates real-time quality inspections into the production line, controls material integrity, and implements rigorous testing protocols. Continuous feedback allows the team to improve product designs regularly.

4. Are customization options available for different clients?

Yes, Hebei Gurui offers customized designs and material options. The R&D team collaborates with clients to develop bespoke products based on branding, product specifications, and logistical considerations.

5. How does Gurui stay ahead of packaging trends?

The R&D team conducts market analysis and partners with academic and industry leaders. They are adept at prototype development, allowing quick adaptation and launch of new products aligned with emerging consumer and regulatory demands.