Content Menu

● 1. Understanding Disposable Spoons

>> 1.1 Types of Materials Used

● 2. Production Costs Breakdown

>> 2.1 Raw Material Costs

>> 2.2 Manufacturing Costs

● 3. Total Cost Calculation

● 4. Economic Implications

>> 4.1 Market Pricing

>> 4.2 Environmental Considerations

● 5. The Manufacturing Process in Detail

>> 5.1 Material Preparation

>> 5.2 Injection Molding Setup

>> 5.3 Cooling and Ejection

● 6. Environmental Impact of Disposable Spoons

● 7. Alternatives and Innovations

● 8. Conclusion

● FAQs

>> 1. Can disposable spoons be recycled?

>> 2. What are the most eco-friendly alternatives to plastic spoons?

>> 3. How does the manufacturing process affect cost?

>> 4. What factors influence the retail price of disposable spoons?

>> 5. Are there any regulations affecting disposable cutlery production?

● Citations:

Disposable spoons are a ubiquitous part of modern dining, especially in fast food and takeout scenarios. However, the economics behind their production is complex, involving various factors such as material costs, manufacturing processes, and market demand. This article explores the cost of producing a single disposable spoon, delving into the materials used, the manufacturing processes involved, and the economic implications of disposable cutlery.

1. Understanding Disposable Spoons

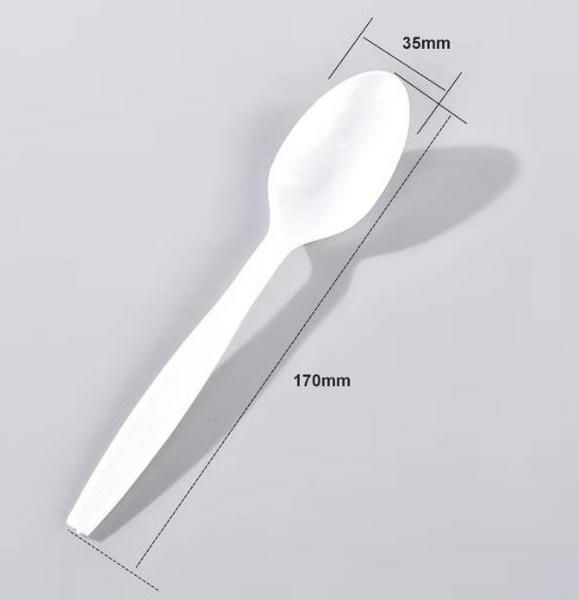

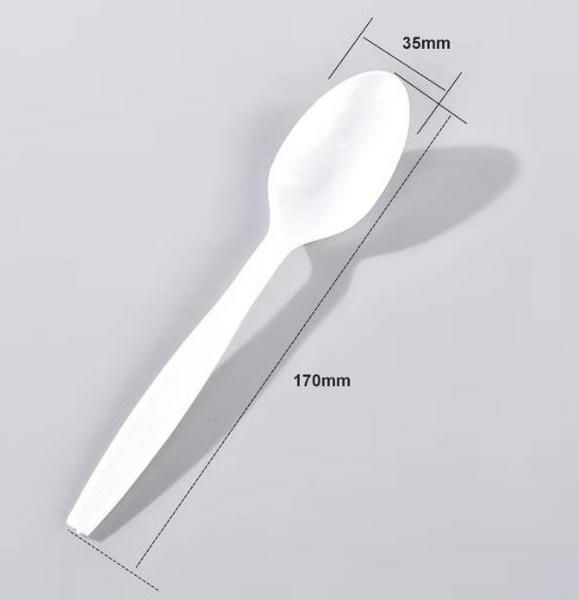

Disposable spoons are primarily made from plastic materials like polypropylene (PP) and polystyrene (PS). These materials are favored for their lightweight properties and cost-effectiveness. The choice of material significantly impacts the overall production cost.

1.1 Types of Materials Used

- Polypropylene (PP): Known for its flexibility and resistance to heat, PP is commonly used for disposable spoons. It can be produced at a lower cost compared to other materials.

- Polystyrene (PS): This material is rigid and provides a sturdy structure, making it suitable for heavier foods. However, it is less flexible than PP.

- Biodegradable Plastics: As environmental concerns rise, biodegradable options made from cornstarch or other organic materials are becoming popular. These tend to be more expensive due to higher raw material costs.

2. Production Costs Breakdown

To estimate how much it costs to make one disposable spoon, we need to consider several factors:

2.1 Raw Material Costs

The price of raw materials fluctuates based on market conditions. Here's an approximate breakdown:

- Polypropylene Pellets: Approximately $0.50 to $0.78 per kilogram.

- Polystyrene Pellets: Generally cheaper than PP but varies based on market demand.

- Biodegradable Materials: Can range from $1.00 to $2.00 per kilogram.

For instance, if we consider that it takes about 2 grams of material to produce one spoon:

- For PP:

Cost per spoon=0.65 USD kg×0.002 kg/1=0.0013 USD

or approximately $0.0013 per spoon.

2.2 Manufacturing Costs

The manufacturing process involves several steps:

- Injection Molding: This is the primary method used for producing plastic spoons. The process requires machinery that can cost between $20,000 to $200,000 depending on capacity and automation levels.

- Labor Costs: Labor costs vary by region but can add approximately $0.01 to $0.03 per spoon depending on automation levels in the production line.

- Overhead Costs: These include utilities, maintenance of machinery, and other operational costs which can add another $0.005 to $0.02 per spoon.

3. Total Cost Calculation

Combining all these factors gives us an estimated total cost for producing one disposable spoon:

Total Cost=Raw Material Cost+Manufacturing Cost+Overhead

Using our previous calculations:

Total Cost=0.0013+0.02+0.01=0.0323 USDTotal Cost=0.0013+0.02+0.01=0.0323 USD

Thus, the estimated cost to produce one disposable plastic spoon is approximately $0.0323, or about 3 cents per spoon.

4. Economic Implications

4.1 Market Pricing

The retail price of disposable spoons typically ranges from $0.01 to $0.05 each when purchased in bulk, depending on the quality and type of material used.

4.2 Environmental Considerations

As environmental regulations become stricter globally, manufacturers are increasingly pressured to switch from traditional plastics to biodegradable options, which can significantly increase production costs but may also lead to higher retail prices.

5. The Manufacturing Process in Detail

Understanding the manufacturing process is essential for comprehending the costs involved in producing disposable spoons.

5.1 Material Preparation

The first step in manufacturing involves preparing the polypropylene pellets:

- The pellets are dried to prevent defects during molding.

- They are then heated until they reach a temperature of about 110°C before being loaded into the injection molding machine.

5.2 Injection Molding Setup

Once prepared, the pellets are injected into molds:

- The injection molding machine heats the pellets until they melt into a thick liquid.

- This molten plastic is injected into molds at high pressure using hydraulic valves.

5.3 Cooling and Ejection

After filling the molds:

- Water circulates through the molds to cool and solidify the plastic quickly.

- Once cooled, ejectors push out the finished spoons for collection and packaging.

6. Environmental Impact of Disposable Spoons

While convenient, disposable spoons contribute significantly to environmental degradation:

- Plastic utensils can take up to 1,000 years to decompose in landfills.

- They often break down into microplastics that contaminate soil and waterways, posing risks to wildlife and human health.

7. Alternatives and Innovations

With growing awareness about environmental issues related to plastic waste, several alternatives have emerged:

- Biodegradable Cutlery: Made from plant-based materials that decompose more easily than traditional plastics.

- Reusable Options: Encouraging consumers to carry their utensils can significantly reduce single-use plastic waste.

8. Conclusion

The production cost of a single disposable spoon is influenced by various factors including raw material prices, manufacturing processes, and overhead costs. Currently estimated at around 3 cents per spoon for traditional plastic options, this figure may rise with shifts towards more sustainable materials.

FAQs

1. Can disposable spoons be recycled?

Yes, most plastic spoons can be recycled if cleaned properly; however, many recycling facilities do not accept them due to contamination concerns.

2. What are the most eco-friendly alternatives to plastic spoons?

Biodegradable spoons made from cornstarch or bamboo are considered eco-friendly alternatives as they decompose more easily than traditional plastics.

3. How does the manufacturing process affect cost?

The manufacturing process affects costs through machinery investment and labor requirements; automated processes tend to lower labor costs but require significant upfront investment.

4. What factors influence the retail price of disposable spoons?

Factors include material type, production scale, market demand, and additional features like branding or packaging requirements.

5. Are there any regulations affecting disposable cutlery production?

Yes, many regions are implementing regulations that limit or ban single-use plastics in favor of more sustainable options.

Citations:

[1] https://pazard.com/plastic-spoon-making-machine/

[2] https://ahimsahome.com/blogs/childrens-health-blog/the-surprising-impact-of-plastic-utensils-on-our-planet

[3] https://covrpack.es/en/blogs/news-on-the-recycling-of-single-use-packaging/the-history-of-disposable-cutlery

[4] https://inochiglobal.com/plastic-spoon-manufacturing-process/

[5] https://www.anchenggy.com/blog/why-is-plastic-cutlery-bad-for-the-environment-understanding-the-harmful-impact.html

[6] https://www.pickonus.com/blogs/default-blog/from-conveniences-to-environmental-concerns-a-chronicle-of-disposable-tableware-in-events-and-everyday-dining

[7] https://www.kviconline.gov.in/pmegp/pmegpweb/docs/commonprojectprofile/PlasticSpoons.pdf

[8] https://www.thegoodboutique.com/inspiration/the-environmental-impact-of-disposable-tableware-and-sustainable-alternatives

[9] https://www.solinatra.com/news/the-evolution-of-cutlery

[10] https://www.quitplastic.in/post/the-environmental-impact-of-traditional-disposable-tableware

[11] https://www.buerkle.de/en/laboplast-r-spoon-disposable_p5378-0011

[12] https://www.forbes.com/sites/lauratenenbaum/2019/07/16/plastic-cutlery-is-terrible-for-the-environment-and-we-dont-need-to-have-it-delivered/

[13] https://www.anchenggy.com/blog/from-wooden-spoons-to-disposable-cutlery-the-fascinating-history-of-utensils.html

[14] https://cnhaijiang.en.made-in-china.com/product/gsmQIkSwXeWE/China-Spoon-Plastic-Disposable-Production-Line-Cost-Plastic-Spoon-with-Logo-Design-Plastic-Spoon-in-Lid-Making-Machine-in-China.html

[15] https://nylcv.org/news/skip-the-stuff-a-simple-solution-to-the-single-use-plastics-epidemic/

[16] https://superiorplastics.com/plastic-products/the-history-of-plasticware/

[17] https://nbsurui.en.made-in-china.com/product/XEZYvKuHnahW/China-90ton-Plastic-Disposable-Spoon-Making-for-Injection-Molding-Machine.html

[18] https://www.youtube.com/watch?v=A-Ck6bbjoWk

[19] https://www.inchel.com/en/NewsDetail/4163311.html

[20] https://en.wikipedia.org/wiki/Disposable_food_packaging