Content Menu

● What Are Disposable Trays?

● Types of Disposable Trays and Key Materials

>> 1. Plastic Trays

>> 2. Paper and Pulp Trays

>> 3. Aluminum Foil Trays

● Top U.S. Disposable Tray Manufacturers and Suppliers

>> Plastic Disposable Tray Manufacturers and Suppliers

>> Paper and Pulp Disposable Tray Manufacturers and Suppliers

>> Aluminum Foil Disposable Tray Manufacturers and Suppliers

● How Disposable Trays Are Manufactured

>> Plastic Tray Manufacturing Process

>> Paper Tray Manufacturing Process

>> Aluminum Foil Tray Manufacturing Process

● Compliance, Sustainability, and Certifications

>> Food Safety Compliance

>> Environmental Standards

>> Sustainability Initiatives

● Innovations in Disposable Tray Materials

● Advances in Manufacturing Technology

● Environmental Impact and Recycling Challenges

● Market Trends and Consumer Preferences

● Sustainability Challenges and Industry Responses

● Future Outlook for Disposable Tray Market

● Customization and Quality Control in Disposable Tray Production

● Industry Certifications and Customer Service Excellence

● Market Challenges and Opportunities

● Conclusion

● Frequently Asked Questions

>> 1. What materials are most commonly used for disposable trays in the U.S.?

>> 2. Are disposable trays safe for food contact?

>> 3. Can I order custom-designed disposable trays?

>> 4. Are there eco-friendly disposable tray options?

>> 5. What is the typical lead time for bulk or custom tray orders?

Disposable tray manufacturers and suppliers play a crucial role in the U.S. foodservice, retail, catering, and healthcare industries. With growing demand for convenience, hygiene, and sustainability, the market for disposable trays—spanning plastic, paper, and aluminum materials—has never been more dynamic. This article explores the leading disposable tray manufacturers and suppliers in the United States, their product offerings, manufacturing processes, compliance standards, and how to choose the right partner for your business.

What Are Disposable Trays?

Disposable trays are single-use serving or packaging solutions designed for food, medical, laboratory, and industrial applications. They are valued for:

- Convenience: No cleaning required after use.

- Hygiene: Single-use minimizes contamination risk.

- Versatility: Available in various sizes, shapes, and materials for diverse needs.

- Sustainability: Many options are compostable or recyclable.

Types of Disposable Trays and Key Materials

1. Plastic Trays

- Materials: Polypropylene (PP), Polyethylene Terephthalate (PET), Polystyrene (PS), High Impact Polystyrene (HIPS).

- Applications: Food packaging, catering, medical, industrial.

- Features: Lightweight, durable, customizable, sometimes recyclable or compostable.

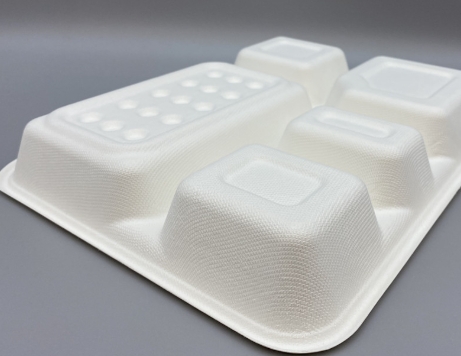

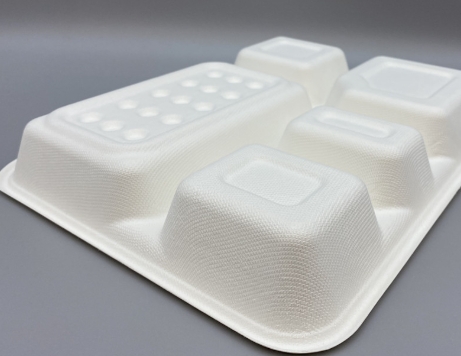

2. Paper and Pulp Trays

- Materials: Kraft paper, paperboard, molded fiber, corrugated board, PLA starch blends.

- Applications: Food service, bakery, produce, eco-friendly events.

- Features: Compostable, recyclable, grease-resistant, customizable printing.

3. Aluminum Foil Trays

- Materials: Food-grade aluminum.

- Applications: Baking, roasting, food storage, catering.

- Features: Oven-safe, recyclable, heat-resistant.

Top U.S. Disposable Tray Manufacturers and Suppliers

The U.S. boasts a robust ecosystem of disposable tray manufacturers and suppliers, each with unique strengths and specialties. Below is a curated list of leading companies by material type.

Plastic Disposable Tray Manufacturers and Suppliers

| Company Name | Location | Specialties & Capabilities |

| Duo Form | Edwardsburg, MI | Precision vacuum-formed plastic trays, custom solutions, food and industrial applications. |

| Hi-Rel Plastics & Molding | Riverside, CA | Thermoforming, custom plastic trays for food, healthcare, and electronics. |

| Robinson Industries | Coleman, MI | Thermoformed and injection-molded trays, reusable and heavy-duty options. |

| Ready-Made Plastic Trays | USA | HIPS thermoform trays, PET lids, custom colors, clear trays, food-grade and recyclable options. |

| Tek Pak, Inc. | USA | Thermoformed trays from APET, polystyrene, polyethylene; custom sizes. |

| Indepak | USA | Custom trays: PET, PP, PVC, HDPE, HIPS; FDA approved, high-volume runs. |

| Mann-Pak, Inc. | USA | Rigid polypropylene trays for meat, snacks, bakery; USDA/FDA approved. |

Paper and Pulp Disposable Tray Manufacturers and Suppliers

| Company Name | Location | Specialties & Capabilities |

| Packform USA LLC | USA | Chipboard, cardboard, honeycomb, corrugated plastic, eco paper trays. |

| Stephen Gould | USA | Pulp and fiber trays, thermoformed options, custom solutions. |

| Deluxe Packaging | USA | Recycled paperboard trays, food and material handling, custom printing. |

| RotondiCo. | USA | Paper, PLA starch, PET trays, private labeling, FDA approved. |

| Atlantic Paper & Supply | USA | Molded fiber trays, compostable, custom box printing. |

| PaperTech | USA | Thermoformed paperboard trays, custom printing for restaurants and bakeries. |

Aluminum Foil Disposable Tray Manufacturers and Suppliers

| Company Name | Location | Specialties & Capabilities |

| Handi-foil of America, Inc. | USA | Aluminum foil trays, baking pans, steam table pans, food containers. |

| D&W Fine Pack | USA | Aluminum trays for foodservice, retail, institutional, sustainability focus. |

| Reynolds Group Holdings | USA | Aluminum foil trays, retail and foodservice, high durability. |

| Pactiv Corporation | USA | Takeout containers, catering trays, customizable, eco-friendly. |

| Penny Plate, LLC | USA | Portion containers, catering trays, innovative designs. |

| Wyda Packaging USA | USA | Standard and custom aluminum trays, eco-friendly materials. |

How Disposable Trays Are Manufactured

Plastic Tray Manufacturing Process

- Raw Material Selection: Food-grade plastic pellets (PP, PET, HIPS) are chosen for safety and performance.

- Thermoforming/Blister Molding: Plastic sheets are heated and shaped in molds to form trays of various sizes and shapes.

- Cutting and Finishing: Trays are trimmed, inspected, and packaged for shipment.

- Customization: Options include color, branding, compartmentalization, and anti-static coatings for specialized uses.

Paper Tray Manufacturing Process

- Material Preparation: Kraft paper or molded fiber is sourced, often from recycled content.

- Forming: Paper is pressed or thermoformed into tray shapes, sometimes with added coatings for grease or moisture resistance.

- Printing and Branding: Custom graphics or logos are added as needed.

- Cutting and Packaging: Trays are cut to size and packed for distribution.

Aluminum Foil Tray Manufacturing Process

- Foil Rolling: Aluminum is rolled into thin sheets.

- Stamping/Forming: Sheets are stamped into tray shapes using high-pressure molds.

- Edge Curling and Reinforcement: Edges are curled for strength and safety.

- Quality Control: Each tray is checked for uniformity and strength before shipment.

Compliance, Sustainability, and Certifications

Food Safety Compliance

- FDA Approval: All food-contact trays must be made from FDA-approved materials to ensure no harmful chemicals leach into food.

- USDA Approval: Especially relevant for meat and poultry trays.

Environmental Standards

- Compostable and Recyclable Options: Many suppliers offer trays made from biodegradable materials (PLA, bagasse, kraft paper) or recyclable plastics and aluminum.

- Certifications: Look for CMA (Compost Manufacturing Alliance), RoHS, and other relevant certifications.

Sustainability Initiatives

- Eco-Friendly Materials: Increasing use of recycled content and plant-based plastics.

- Lean Manufacturing: Many U.S. manufacturers adopt lean and Kaizen/5S practices to minimize waste.

Innovations in Disposable Tray Materials

Recent innovations in disposable tray materials have focused on enhancing sustainability and functionality. Biodegradable plastics derived from plant-based sources such as polylactic acid (PLA) are gaining popularity due to their reduced environmental impact. Additionally, hybrid trays combining paper and plastic layers offer improved durability while maintaining compostability.

Advances in Manufacturing Technology

Manufacturers are increasingly adopting automation and robotics in the production process to improve precision and reduce waste. Advanced thermoforming techniques allow for more intricate designs and better material utilization. These technological advancements contribute to cost savings and higher quality products.

Environmental Impact and Recycling Challenges

While many disposable trays are recyclable, contamination from food residues often hinders recycling efforts. Efforts to educate consumers and improve tray design for easier cleaning are underway. Some manufacturers are also exploring closed-loop recycling systems to reclaim materials and reduce landfill waste.

Market Trends and Consumer Preferences

The demand for eco-friendly disposable trays is driven by consumer awareness and regulatory pressures. Brands are increasingly marketing their products as sustainable, which influences purchasing decisions. Customization options, such as branding and compartmentalization, also play a significant role in meeting diverse market needs.

Sustainability Challenges and Industry Responses

The disposable tray industry faces significant challenges in balancing convenience with environmental responsibility. Many manufacturers are investing in research to develop trays that break down more quickly in composting environments without compromising strength or safety. Industry collaborations are also forming to standardize labeling and recycling instructions to reduce consumer confusion.

Future Outlook for Disposable Tray Market

The market for disposable trays is expected to grow steadily, driven by increasing demand in food delivery, healthcare, and retail sectors. Innovations in materials science and manufacturing processes will likely lead to more sustainable and cost-effective products. Companies that prioritize environmental stewardship and customer customization will have a competitive advantage.

Customization and Quality Control in Disposable Tray Production

Customization is a key differentiator among disposable tray manufacturers. Many companies offer tailored solutions including unique shapes, sizes, compartmentalization, and branding options to meet specific client needs. Quality control processes are stringent, involving multiple inspection stages to ensure product consistency, safety, and compliance with regulatory standards.

Manufacturers often employ advanced testing methods such as stress testing, leak testing, and material composition analysis to maintain high standards. These efforts help build trust with clients and end consumers, ensuring that disposable trays perform reliably in various applications.

Industry Certifications and Customer Service Excellence

Industry certifications such as ISO 9001, ISO 14001, and HACCP are critical indicators of a manufacturer's commitment to quality and environmental management. These certifications assure customers that the products meet international standards for safety, quality, and sustainability.

Exceptional customer service is another hallmark of leading disposable tray suppliers. Responsive communication, flexible order management, and after-sales support help build long-term partnerships. Many suppliers also provide technical assistance and product training to ensure optimal use of their trays.

Market Challenges and Opportunities

The disposable tray market faces challenges such as fluctuating raw material costs, regulatory changes, and increasing competition from reusable alternatives. However, these challenges also present opportunities for innovation and differentiation.

Manufacturers that invest in sustainable materials, efficient production methods, and customer-centric solutions are well-positioned to capitalize on growing demand. Strategic partnerships and market expansion into emerging sectors like meal delivery and healthcare can drive future growth.

Conclusion

Choosing the right disposable tray manufacturer or supplier is essential for meeting your business needs while ensuring quality, compliance, and sustainability. By understanding the materials, manufacturing processes, and certifications, you can make an informed decision that supports your brand and environmental goals.

Frequently Asked Questions

1. What materials are most commonly used for disposable trays in the U.S.?

Plastic (PP, PET, HIPS), paper/pulp (kraft, molded fiber), and aluminum foil are the most common materials.

2. Are disposable trays safe for food contact?

Yes, when manufactured from FDA- or USDA-approved materials. Always confirm food safety compliance with your supplier.

3. Can I order custom-designed disposable trays?

Most leading manufacturers offer custom shapes, sizes, colors, and branding to meet your specific needs.

4. Are there eco-friendly disposable tray options?

Many suppliers offer compostable, biodegradable, or recyclable trays made from kraft paper, bagasse, PLA, or recycled plastics and aluminum.

5. What is the typical lead time for bulk or custom tray orders?

Lead times vary: stock trays can ship in days, while custom orders may take several weeks. Always check with your supplier for accurate timelines.