Content Menu

● Understanding Disposable Cup Thermoforming Machines

● Factors Influencing Disposable Cup Thermoforming Machine Price

● Current Price Range in 2025

● Key Features That Impact Price

● Comparing Disposable Cup Thermoforming Machine Prices

● Market Trends Affecting Pricing

● How to Choose the Right Disposable Cup Thermoforming Machine

● The Investment Perspective

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What factors influence the disposable cup thermoforming machine price?

>> 2. Can a single machine produce different cup sizes and materials?

>> 3. How do I determine the right machine for my production needs?

>> 4. What is the expected lifespan of a disposable cup thermoforming machine?

>> 5. Are there ongoing costs after purchasing a disposable cup thermoforming machine?

The global demand for disposable cups, driven by the foodservice, beverage, and hospitality industries, has led to a surge in the need for efficient and reliable disposable cup thermoforming machines. If you are considering investing in this essential manufacturing equipment, understanding the current price of a disposable cup thermoforming machine is crucial. This article provides a comprehensive exploration of disposable cup thermoforming machine price, the factors influencing cost, key features to look for, and guidance for buyers in 2025.

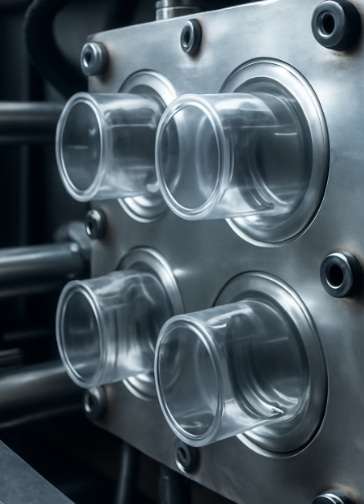

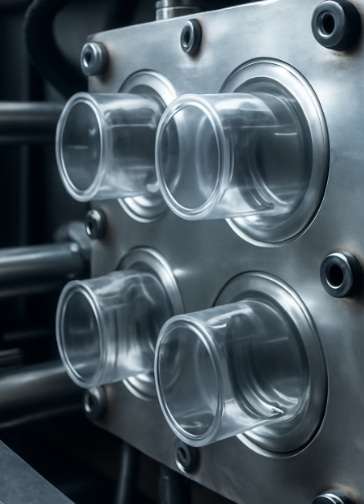

Understanding Disposable Cup Thermoforming Machines

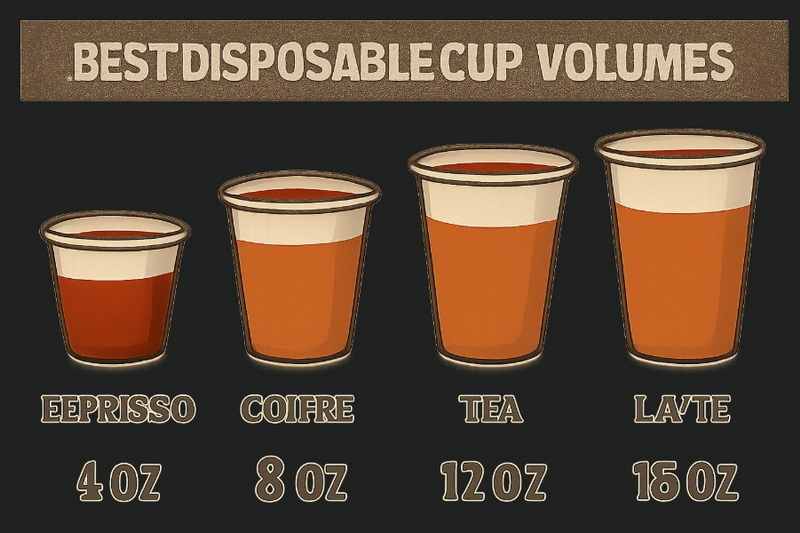

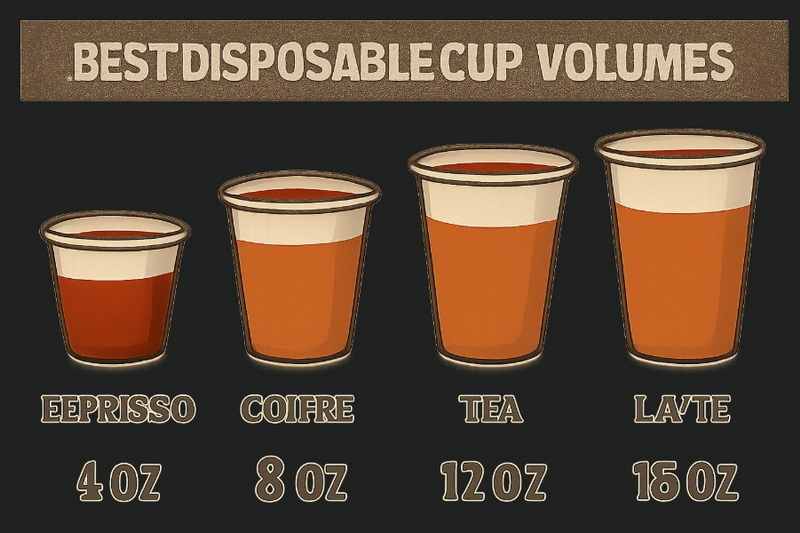

Disposable cup thermoforming machines are specialized equipment designed to manufacture cups from plastic or paper sheets using heat and pressure. These machines automate the processes of heating, forming, cutting, and stacking, enabling mass production of uniform, high-quality disposable cups. The versatility of these machines allows for the production of various cup sizes and shapes, catering to diverse market requirements.

Factors Influencing Disposable Cup Thermoforming Machine Price

The disposable cup thermoforming machine price is influenced by several key factors:

- Machine Type and Automation Level: Fully automatic machines with advanced features command higher prices due to their increased production capacity and reduced labor requirements.

- Production Capacity: Machines capable of producing higher volumes of cups per hour generally cost more.

- Material Compatibility: Machines that can process a wider range of materials (such as PET, PP, PS, PLA, and paper) tend to be more expensive.

- Precision and Technology: Advanced control systems, servo-driven mechanisms, and user-friendly interfaces increase the cost.

- Brand and Origin: Machines from reputable manufacturers or those with international certifications usually have higher price tags.

- Customization and Additional Features: Options like robotic stacking, quick mold change systems, and enhanced safety features add to the overall price.

Current Price Range in 2025

As of 2025, the disposable cup thermoforming machine price typically falls within a broad range, reflecting the diversity of models and capabilities available in the market:

- Entry-Level and Semi-Automatic Machines: These models generally start from the lower end of the price spectrum, making them suitable for small-scale manufacturers or startups.

- Fully Automatic and High-Capacity Machines: Prices for these advanced machines are significantly higher, justified by their speed, efficiency, and ability to handle large-scale production.

The most common price range for a new disposable cup thermoforming machine is between the lower tens of thousands and up to several hundred thousand, depending on the aforementioned factors. Buyers should always request detailed quotations from suppliers to understand what is included in the price, such as installation, training, and after-sales support.

Key Features That Impact Price

When evaluating the disposable cup thermoforming machine price, it is essential to consider the features that contribute to both performance and cost:

- Material Versatility: Machines that can process multiple types of thermoplastics or paper offer greater flexibility but may cost more.

- Production Speed: Faster machines with higher cycle rates enhance productivity and justify a higher investment.

- Energy Efficiency: Modern machines often incorporate energy-saving technologies, reducing long-term operating costs.

- Ease of Operation: Touchscreen controls, programmable settings, and automated diagnostics improve usability and may increase the price.

- Maintenance and Durability: Robust construction, accessible components, and comprehensive support services are reflected in the price.

- Safety Features: Compliance with safety standards and inclusion of emergency stop systems are critical, especially for export markets.

Comparing Disposable Cup Thermoforming Machine Prices

| Machine Type | Typical Price Range | Key Features | Suitable For |

| Entry-Level/Semi-Automatic | Lower tens of thousands | Basic automation, moderate speed, limited options | Small businesses, startups |

| Mid-Range Automatic | Mid tens of thousands | Higher speed, more material options, user-friendly | Growing manufacturers |

| High-End Fully Automatic | Up to several hundred thousand | Maximum speed, advanced controls, high output | Large-scale production, exporters |

The table above illustrates how the disposable cup thermoforming machine price varies according to the level of automation, production speed, and feature set.

Market Trends Affecting Pricing

Several market trends are shaping the disposable cup thermoforming machine price landscape:

- Automation and Digitalization: The shift towards fully automated production lines increases upfront costs but delivers long-term savings through efficiency and reduced labor.

- Sustainability: The demand for machines capable of processing eco-friendly materials (like PLA or biodegradable plastics) is rising, influencing both design and price.

- Customization: Brands seeking unique cup shapes or printed designs drive demand for machines with flexible mold and printing capabilities, affecting overall cost.

- Global Sourcing: The rise of manufacturers in Asia-Pacific, particularly China, has introduced a wider range of price points, making it easier to find machines that fit different budgets.

How to Choose the Right Disposable Cup Thermoforming Machine

Selecting the right machine goes beyond just comparing prices. Here are some steps to ensure a wise investment:

- Assess Production Needs: Determine your required output, cup sizes, and material types.

- Evaluate Space and Infrastructure: Ensure the machine fits your facility and that you have the necessary utilities (power, air supply, etc.).

- Check Supplier Reputation: Opt for suppliers with proven track records, certifications, and reliable after-sales service.

- Request Detailed Quotations: Understand what is included in the price-shipping, installation, training, spare parts, and warranties.

- Plan for Maintenance: Factor in the availability of spare parts and technical support to minimize downtime.

The Investment Perspective

While the initial disposable cup thermoforming machine price may seem substantial, it is important to consider the return on investment. High-quality, efficient machines reduce waste, lower operating costs, and enable manufacturers to meet growing market demand. Over time, the savings in labor, materials, and energy can offset the higher upfront cost of advanced machines.

Conclusion

The disposable cup thermoforming machine price in 2025 spans a wide range, reflecting the diversity of models, capabilities, and features available on the market. Whether you are a small startup or a large-scale manufacturer, understanding the factors that influence price and carefully evaluating your production needs will help you make a sound investment. High-quality machines may require a higher upfront cost, but their efficiency, durability, and flexibility can deliver significant returns over time. As the demand for disposable cups continues to grow, choosing the right thermoforming machine is essential for staying competitive in the global market.

Frequently Asked Questions (FAQ)

1. What factors influence the disposable cup thermoforming machine price?

Several factors impact the price, including the level of automation, production capacity, material compatibility, brand reputation, and additional features such as energy efficiency and safety systems. Machines with higher speeds, advanced controls, and greater versatility generally command higher prices.

2. Can a single machine produce different cup sizes and materials?

Yes, many modern disposable cup thermoforming machines are designed with flexibility in mind. They can accommodate various molds for different cup sizes and are compatible with multiple materials like PET, PP, PS, PLA, and even paper, provided the machine specifications support such versatility.

3. How do I determine the right machine for my production needs?

Start by assessing your required production volume, preferred cup sizes, and the types of materials you wish to use. Consider the available space in your facility and your budget. Consulting with suppliers and industry experts can help match your requirements to the right machine model.

4. What is the expected lifespan of a disposable cup thermoforming machine?

With proper maintenance and regular servicing, a high-quality disposable cup thermoforming machine can last between ten to twenty years or more. The actual lifespan depends on usage intensity, adherence to maintenance schedules, and the quality of the machine itself.

5. Are there ongoing costs after purchasing a disposable cup thermoforming machine?

Yes, ongoing costs include maintenance, replacement parts, energy consumption, and labor. Investing in a machine with high energy efficiency and low maintenance requirements can help reduce these long-term operational expenses.