Content Menu

● The Importance of Eco-Friendly Disposable Cup Printing

● Overview of Disposable Cup Printing Technologies

● Flexographic Printing: Efficiency Meets Sustainability

>> Eco-Friendly Advantages

>> Limitations

>> Best Use Case

● Digital Printing: Precision and Flexibility for Short Runs

>> Eco-Friendly Advantages

>> Limitations

>> Best Use Case

● Offset Printing: High Quality, But Is It Green?

>> Eco-Friendly Advantages

>> Limitations

>> Best Use Case

● Screen Printing: Durable and Versatile, But Not Always Green

>> Eco-Friendly Advantages

>> Limitations

>> Best Use Case

● Inks and Coatings: The Unsung Heroes of Eco-Friendly Printing

● Materials Matter: Paper, PLA, RPET, and Beyond

● Comparing Printing Technologies for Eco-Friendly Disposable Cup Printing

● How to Choose the Best Printing Technology for Eco-Friendly Disposable Cups

● The Role of Certifications and Standards

● The Future of Eco-Friendly Disposable Cup Printing

● Conclusion

● FAQ

>> 1. What is the most eco-friendly printing technology for disposable cups?

>> 2. Can all disposable cup printing methods use compostable inks?

>> 3. How does the choice of ink affect the recyclability or compostability of disposable cups?

>> 4. Are digitally printed disposable cups as durable as those printed with traditional methods?

>> 5. What certifications should I look for when choosing eco-friendly disposable cup printing?

The global movement toward sustainability has transformed every aspect of product development, packaging, and branding. Among the most visible symbols of this shift are disposable cups-ubiquitous in coffee shops, fast-food chains, and at events. As businesses and consumers become more conscious of their environmental impact, the demand for eco-friendly disposable cups has surged. Yet, sustainability is not only about the materials used in the cup itself but also about the methods used to print branding, logos, and designs onto these cups. The choice of printing technology plays a crucial role in determining the overall eco-friendliness of disposable cup printing.

This article explores the various printing technologies available for disposable cup printing, analyzes their environmental impact, and identifies which methods best align with eco-friendly values. We will delve into the materials, inks, and processes that contribute to a greener future, helping businesses make informed decisions that benefit both their brand and the planet.

The Importance of Eco-Friendly Disposable Cup Printing

Disposable cups are often made from materials like paper, plastic, or bioplastics. While switching to compostable or recyclable materials is a significant step, the environmental impact of disposable cup printing cannot be overlooked. The choice of ink, energy consumption, waste generation, and recyclability of printed cups all factor into the sustainability equation.

Eco-friendly disposable cup printing ensures that:

- The cups remain compostable or recyclable after branding.

- Harmful chemicals are not introduced into the environment.

- The carbon footprint of the printing process is minimized.

- The final product aligns with consumer expectations for sustainability.

Businesses that prioritize eco-friendly disposable cup printing not only reduce their environmental impact but also enhance their brand image and appeal to environmentally conscious customers.

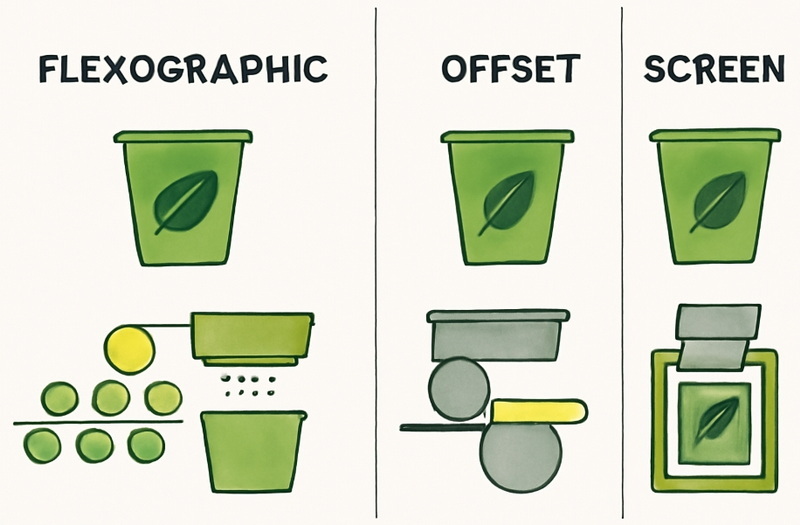

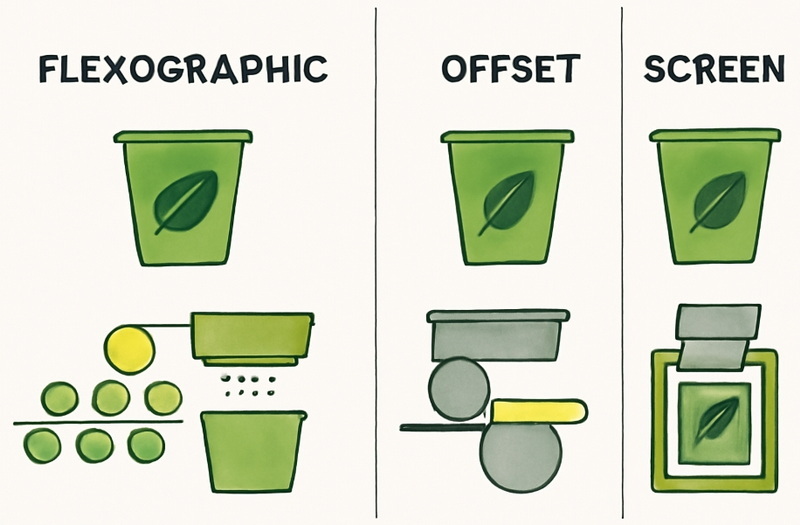

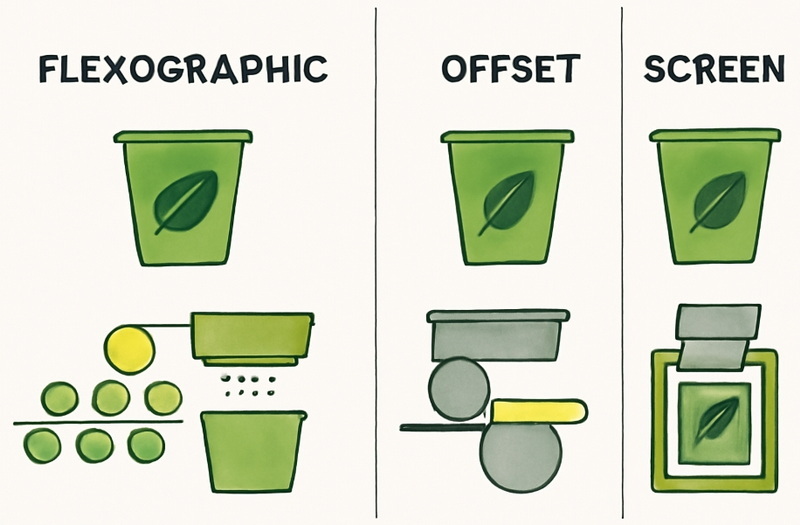

Overview of Disposable Cup Printing Technologies

Several printing technologies are commonly used for disposable cups. Each has unique characteristics, advantages, and environmental considerations. The main methods include:

- Flexographic Printing

- Digital Printing

- Offset Printing

- Screen Printing

Let's examine each technology in detail, focusing on their suitability for eco-friendly disposable cup printing.

Flexographic Printing: Efficiency Meets Sustainability

Flexographic printing, or flexo printing, is a popular choice for high-volume disposable cup printing. This method uses flexible printing plates and is renowned for its speed, efficiency, and adaptability to various substrates, including paper and bioplastics.

Eco-Friendly Advantages

- Water-Based Inks: Flexographic printing often employs water-based inks, which are less harmful to the environment compared to solvent-based alternatives. These inks are free from volatile organic compounds, reducing air pollution and health risks for workers.

- High Efficiency: Flexo printing is ideal for large production runs, minimizing energy consumption and waste per cup.

- Substrate Versatility: The method accommodates a wide range of eco-friendly materials, such as compostable paper, PLA-coated paper, and recycled content.

Limitations

- Color Range: Flexo printing may offer a more limited color palette compared to offset printing, which could restrict intricate or highly detailed designs.

- Setup Costs: The initial setup requires the creation of printing plates, making it less cost-effective for very short runs.

Best Use Case

Large-scale production of branded eco-friendly disposable cups where efficiency and sustainability are top priorities.

Digital Printing: Precision and Flexibility for Short Runs

Digital printing has revolutionized disposable cup printing, offering exceptional flexibility, precision, and speed. Unlike traditional methods, digital printing does not require plates, making it ideal for short runs and custom designs.

Eco-Friendly Advantages

- Reduced Waste: Without the need for plates, digital printing eliminates plate-making waste and allows for on-demand production, reducing excess inventory.

- Efficient Ink Usage: Digital printers apply ink only where needed, minimizing waste.

- Compatibility with Eco-Friendly Inks: Many digital printers can use water-based or other environmentally friendly inks.

- Customization: Perfect for limited-edition runs, event-specific branding, or personalized cups, reducing the risk of overproduction.

Limitations

- Higher Unit Costs for Large Runs: While cost-effective for small batches, digital printing can be more expensive per cup for large-scale orders.

- Ink Limitations: Not all digital inks are compostable or recyclable, so careful selection is necessary.

Best Use Case

Small to medium runs of eco-friendly disposable cups requiring high-quality, detailed, or personalized designs.

Offset Printing: High Quality, But Is It Green?

Offset printing is known for its superior image quality and color accuracy. It is widely used for various packaging applications, including disposable cup printing.

Eco-Friendly Advantages

- High-Quality Results: Produces sharp images and vibrant colors, enhancing brand visibility.

- Efficient for Large Runs: Economical for high-volume orders.

Limitations

- Ink Concerns: Traditional offset printing often uses oil-based inks, which may contain chemicals that are not environmentally friendly. However, some printers now offer vegetable-based or soy-based inks as greener alternatives.

- Plate Production: Like flexo, offset printing requires plates, generating waste and increasing energy consumption.

- Not Always Compatible with Compostable Substrates: Some offset inks and processes can compromise the compostability or recyclability of eco-friendly cups.

Best Use Case

Large orders where image quality is paramount and when using eco-friendly inks and substrates.

Screen Printing: Durable and Versatile, But Not Always Green

Screen printing is a versatile technique suitable for a variety of cup materials, including plastic, paper, and bioplastics. It is often used for reusable and souvenir cups but can also be applied to disposable cup printing.

Eco-Friendly Advantages

- Durable Prints: Produces long-lasting designs, which is ideal for reusable cups.

- Color Flexibility: Allows for vibrant, multi-color designs.

Limitations

- Ink Types: Many screen-printing inks are solvent-based, which can be environmentally harmful unless water-based or UV-curable inks are used.

- Waste Generation: The process can generate significant waste, especially during color changes and cleanup.

- Not Ideal for Compostable Cups: Some inks may interfere with compostability or recyclability.

Best Use Case

Specialty disposable cup printing where durability and color vibrancy are required, and when using the most eco-friendly inks available.

Inks and Coatings: The Unsung Heroes of Eco-Friendly Printing

The sustainability of disposable cup printing depends not only on the printing technology but also on the inks and coatings used. Key considerations include:

- Water-Based Inks: Preferred for their low environmental impact and compatibility with compostable and recyclable cups.

- Compostable Inks: Specially formulated to break down in composting environments, ensuring the cup remains fully compostable.

- Vegetable-Based Inks: Derived from renewable resources, these inks reduce reliance on petroleum-based products.

- PLA Coatings: Polylactic acid (PLA) is a plant-based coating used to make paper cups compostable. Printing technologies must be compatible with PLA to maintain compostability.

Businesses should ensure that their disposable cup printing partners use inks and coatings certified for compostability or recyclability, depending on the intended end-of-life scenario for the cups.

Materials Matter: Paper, PLA, RPET, and Beyond

Eco-friendly disposable cups are typically made from:

- Compostable Paper with PLA Coating: Fully compostable in industrial facilities, provided the printing inks are also compostable.

- Recycled PET (RPET): Made from post-consumer recycled plastic, these cups are recyclable and reduce the need for virgin plastic production.

- Bioplastics: Derived from renewable resources, bioplastics like PLA are compostable and suitable for cold beverages.

The printing technology must be compatible with these materials to ensure the cups remain eco-friendly after printing.

Comparing Printing Technologies for Eco-Friendly Disposable Cup Printing

| Printing Technology | Eco-Friendly Features | Best For | Limitations |

| Flexographic | Water-based inks, high efficiency, compatible with compostable/recyclable cups | Large runs, standard designs | Limited color range, plate setup |

| Digital | Minimal waste, customizable, compatible with eco inks | Short runs, custom designs | Higher cost for large runs, ink selection critical |

| Offset | High-quality prints, can use vegetable inks | Large runs, premium branding | Plate waste, ink concerns |

| Screen | Durable prints, color flexibility | Specialty cups, reusable/disposable | Solvent ink concerns, waste generation |

How to Choose the Best Printing Technology for Eco-Friendly Disposable Cups

Selecting the optimal disposable cup printing technology depends on several factors:

- Order Volume: Flexographic and offset printing are best for large runs, while digital printing excels in small, customized batches.

- Cup Material: Ensure the printing method and inks are compatible with compostable or recyclable substrates.

- Design Complexity: Digital and offset printing handle intricate designs better; flexo is ideal for simpler graphics.

- Sustainability Goals: Prioritize water-based, compostable, or vegetable-based inks and ensure the printing process does not compromise the cup's eco-friendly properties.

- Budget and Lead Time: Digital printing offers fast turnaround for short runs, while flexo and offset are more economical for bulk orders.

The Role of Certifications and Standards

To guarantee the eco-friendliness of disposable cup printing, look for certifications such as:

- Compostability Certifications: Certifies compostability of cups and inks in industrial composting settings.

- FSC/PEFC: Ensures paper is sourced from sustainably managed forests.

- Recyclability Certifications: Confirms that cups can be processed through standard recycling streams.

These certifications offer assurance to both businesses and consumers that the disposable cup printing process aligns with recognized environmental standards.

The Future of Eco-Friendly Disposable Cup Printing

Innovation in disposable cup printing continues to advance, with new technologies and materials emerging to further reduce environmental impact. Developments include:

- Advanced Compostable Inks: Designed specifically for compatibility with industrial composting.

- Recyclable Barrier Coatings: Replacing traditional plastic linings with recyclable alternatives.

- On-Demand Printing: Reducing waste by producing only what is needed.

As regulations tighten and consumer expectations rise, the disposable cup printing industry will play a pivotal role in shaping a more sustainable future.

Conclusion

Eco-friendly disposable cup printing is a multifaceted challenge that requires careful consideration of materials, inks, and printing technologies. Flexographic and digital printing currently stand out as the most sustainable options, with flexo leading for large-scale production and digital excelling in customization and short runs. The choice of water-based, compostable, or vegetable-based inks is essential to maintain the eco-friendly integrity of the cups.

Businesses that invest in sustainable disposable cup printing not only contribute to environmental protection but also enhance their brand reputation and customer loyalty. By choosing the right technology and materials, companies can ensure their disposable cups are as green as their intentions.

FAQ

1. What is the most eco-friendly printing technology for disposable cups?

Flexographic printing is generally considered the most eco-friendly for large-scale disposable cup printing due to its use of water-based inks, efficiency, and compatibility with compostable and recyclable materials. For smaller runs or custom designs, digital printing is a sustainable choice when paired with eco-friendly inks.

2. Can all disposable cup printing methods use compostable inks?

Not all printing methods are compatible with compostable inks. Flexographic and digital printing often support water-based or compostable inks, while offset and screen printing may require special formulations to ensure compostability.

3. How does the choice of ink affect the recyclability or compostability of disposable cups?

The ink used in disposable cup printing must be compatible with the cup's end-of-life scenario. Compostable inks are necessary for compostable cups, while recyclable inks should be used for recyclable cups to avoid contamination and ensure proper processing.

4. Are digitally printed disposable cups as durable as those printed with traditional methods?

Digitally printed disposable cups can be highly durable, especially when using high-quality inks and substrates. However, for applications requiring extreme durability or resistance to abrasion, traditional methods like screen printing may offer advantages.

5. What certifications should I look for when choosing eco-friendly disposable cup printing?

Look for certifications such as compostability standards, FSC or PEFC for sustainable paper sourcing, and recyclability certifications for assurance that the cups and prints meet recognized environmental standards.